The Lupin Story

Inspired by Patients

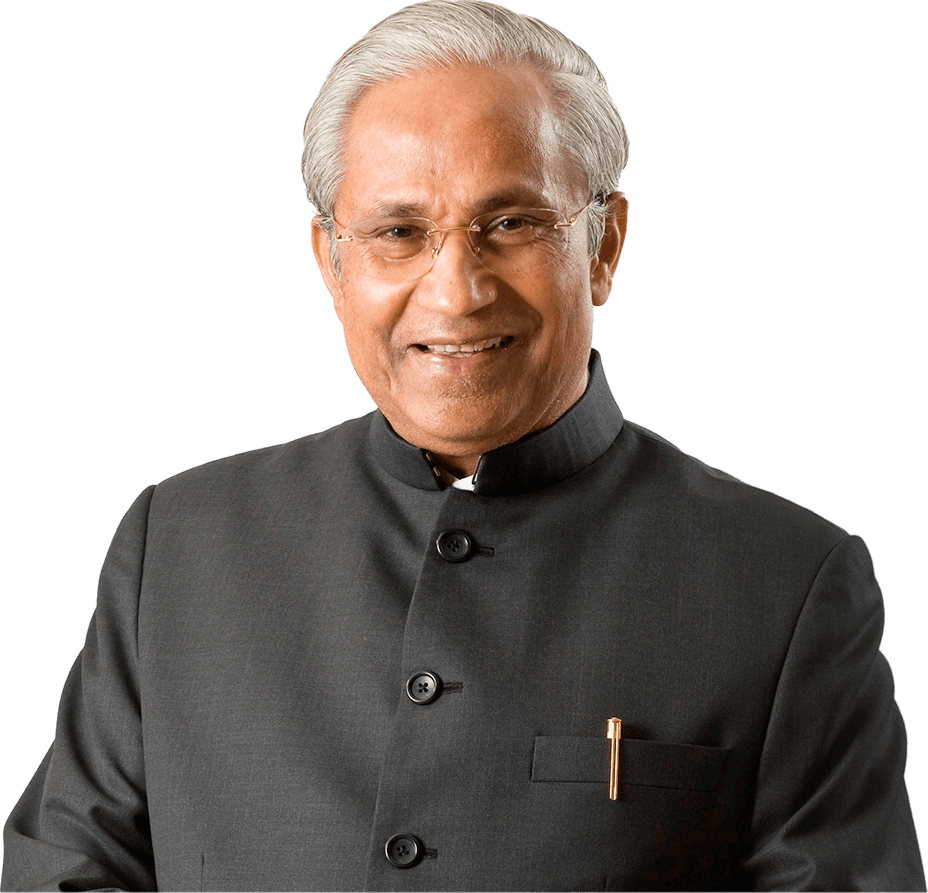

Founded by Dr. Desh Bandhu Gupta in 1968,

Lupin aimed to improve access to essential

medicines. Today we stand tall as a globally

trusted pharmaceutical company guided by

science, quality, and a patient-first mindset.

Our Purpose

Treatments

That Transform

Hope Into

Healing

Ours is a purpose-driven

journey of over 5 decades,

where we aim to improve

lives, build sustainability

and deliver long-term

solutions to all.

Delivering meaningful

treatments for today and

tomorrow

Making complex, cutting-edge

healthcare solutions accessible

to all

Serving markets and patients

overlooked by others

Our Business

Lupin operates a highly diversified pharmaceutical business with a

strong presence across key global markets. Our operations span

generics, complex formulations,

branded products, and other

high-burden specialty segments, supported by robust R&D

and manufacturing capabilities.

Spread across developed and emerging markets, Lupin's business is anchored in patient-centric approach and operational excellence.

Investors

Stock

Quotes

Last updated on —

NSE : —

BSE : —

Sustainability

Caring for People,

Planet, Patients

Our mission extends beyond medicines. We invest

in people, communities, and a greener tomorrow.

Community

Beyond

Medicines

Lupin Foundation works in 5,400+ villages in 8 states of India.

At the core of Lupin's community work is a passion

to build sustainable models for uplifting lives.

Life

at Lupin

Our people are the driving force behind our mission to improve patients’ lives and longevity.